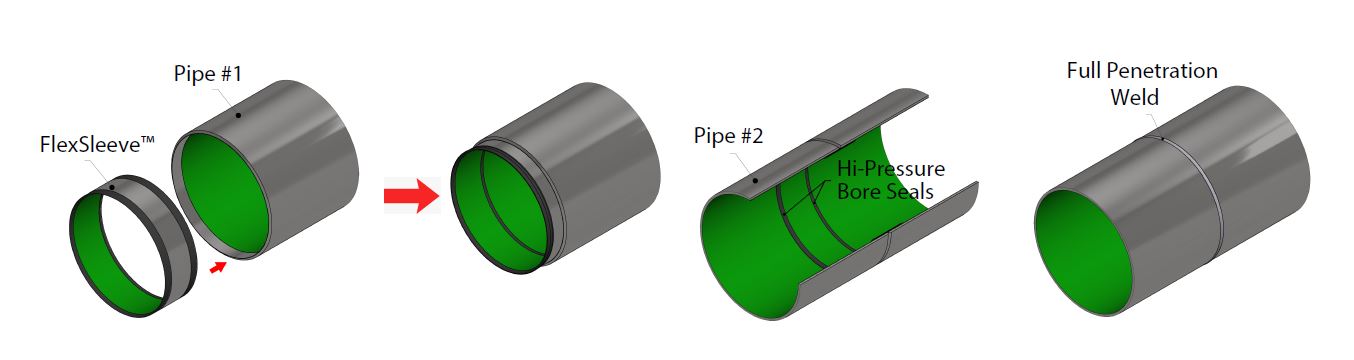

FlexSleeve® for Thin Linings

Internal Sleeve Innovation

Advantages

Flexibility : Thin-gauge assembly adjusts to pipe shape for easy insertion & consistent seal quality.

Sealing : Bore seals accommodate pipe ID tolerances and seal at any pipeline pressure.

Weld Quality : Flexibility allows for a better fit, easier root pass, and more consistent weld quality.

Heat Resistance : Wider sleeve & thicker insulation reduces heat impact & does not slow down welding.

Large Diameters : Accommodates out of round pipe

Automatic Welding : Compatible with internal lineup clamps & automatic welding

Patents Pending

CCB® Sleeve for Thin Linings

The CCB® sleeve is synonymous with internal weld sleeves due to it being one of the original patented products for this technology. It has been used to successfully protect hundreds of thousands of welded pipe joints from internal corrosion over the past 25 years.

Lined Pipe Systems is proud to have acquired this cutting-edge technology and is thrilled to present it as a formidable alternative to FlexSleeve. This holds particularly true for diameters 12” and smaller, where the CCB® sleeve demonstrates optimal functionality, ensuring robust protection for welded pipe joints against internal corrosion. Trust in the reliability and proven performance of the CCB® sleeve for safeguarding your assets in the long term.

Advantages

25+ years of successful case history

Sets market standard for quality

Tighter seal than competitors

Long sloped profile allows for pigs to pass and less head loss

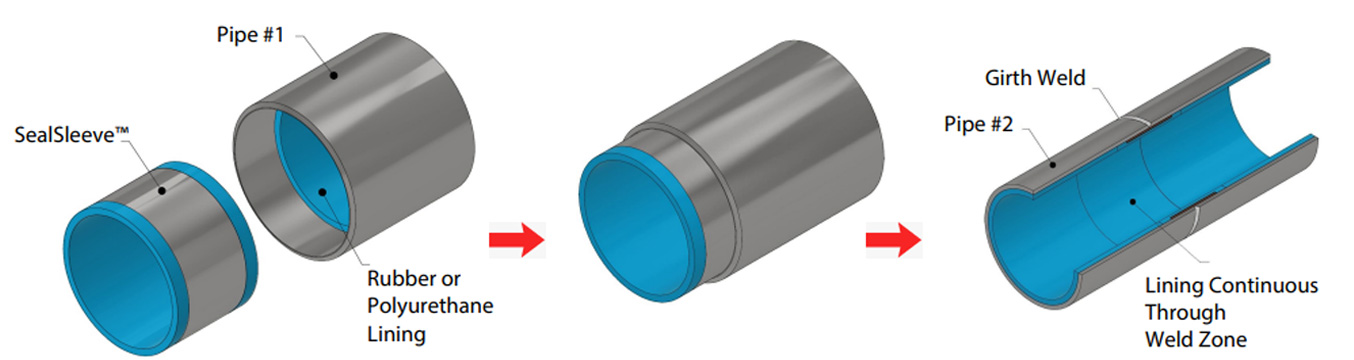

SealSleeve™ for Rubber & PU Linings

Reliable & Economical Slurry Transport

Why SealSleeve™? Owners of slurry pipelines often want to use an abrasion-resistant internal lining to ensure the pipeline lasts. However, mechanical joints have historically been required for lined pipe and the cost can be prohibitive – particularly for higher pressures.

LPS’ SealSleeve™ system allows for standard full penetration welded joints and fast construction of pipe internally lined with rubber and polyurethane. SealSleeve™ is lined with the same polymer as the pipe and has built-in insulation and seals that permit lining continuity through weld zone.

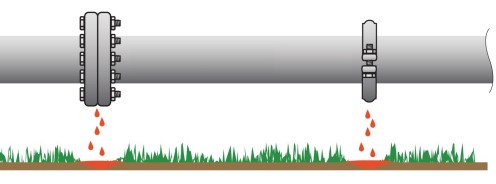

LPS technology makes projects economically feasible that otherwise would not be while eliminating the possibility of leaks that are common with mechanical joints.

Reliable : Rubber and polyurethane linings provide optimal long-term abrasion & corrosion protection.

Cost effective : Far less expensive than flanged joints. Far longer-lasting than pipelines without a lining.

Leak-free : Welded joints are stronger than mechanical joints and eliminate the possibility of leaks.

Permits field bends : Eliminates the need for shop-fabricated custom hot bends on long distance slurry lines.

Easy field length adjustments : Length adjustments / tie-ins with mechanical joints can add weeks or months to a project.

Mechanical joints are expensive, weaker than the pipe wall, and leak-prone

Full penetration welded joints are cost-efficient, as strong as the pipe wall, and leak-free.

How It Works

SealSleeve™ lining thickness and pipe end preparation adjusted to meet project requirements.

Advantages

Aromatic Polyurethane

Excellent long term resistance to

water permeationVery good adhesion to steel

Good abrasion resistance

Withstands stress from pigging and

internal lineup clamps- Sufficient flexibility and elongation for thermal expansion, pipe handling & cold bends

Thermoplastic Polyurethane

- Excellent abrasion resistance & sufficient thickness for highly abrasive slurries

- Superior physical properties (tensile, tear, elongation)

- Very good adhesion to steel

Natural & Synthetic Rubber

Excellent abrasion resistance & sufficient thickness for highly abrasive slurries

Superior resilience and elongation

Excellent adhesion to steel

Synthetic rubbers are resistant to high temperatures & various chemicals

Fusion & Liquid Bonded Epoxy

Cost-efficient corrosion protection for water pipelines

Excellent adhesion to steel

Good chemical resistance

Novolac & phenolic epoxies provide very good heat & chemical resistance

Thermoplastic Polyamides (Nylon)

High flexibility

Good heat resistance

Good abrasion resistance

- Resistant to oils and many chemicals

- Low moisture absorption

Hi-Density Polyethylene

Very low water permeation

Good abrasion resistance

Sufficient thickness to eliminate possibility of liner pinholes