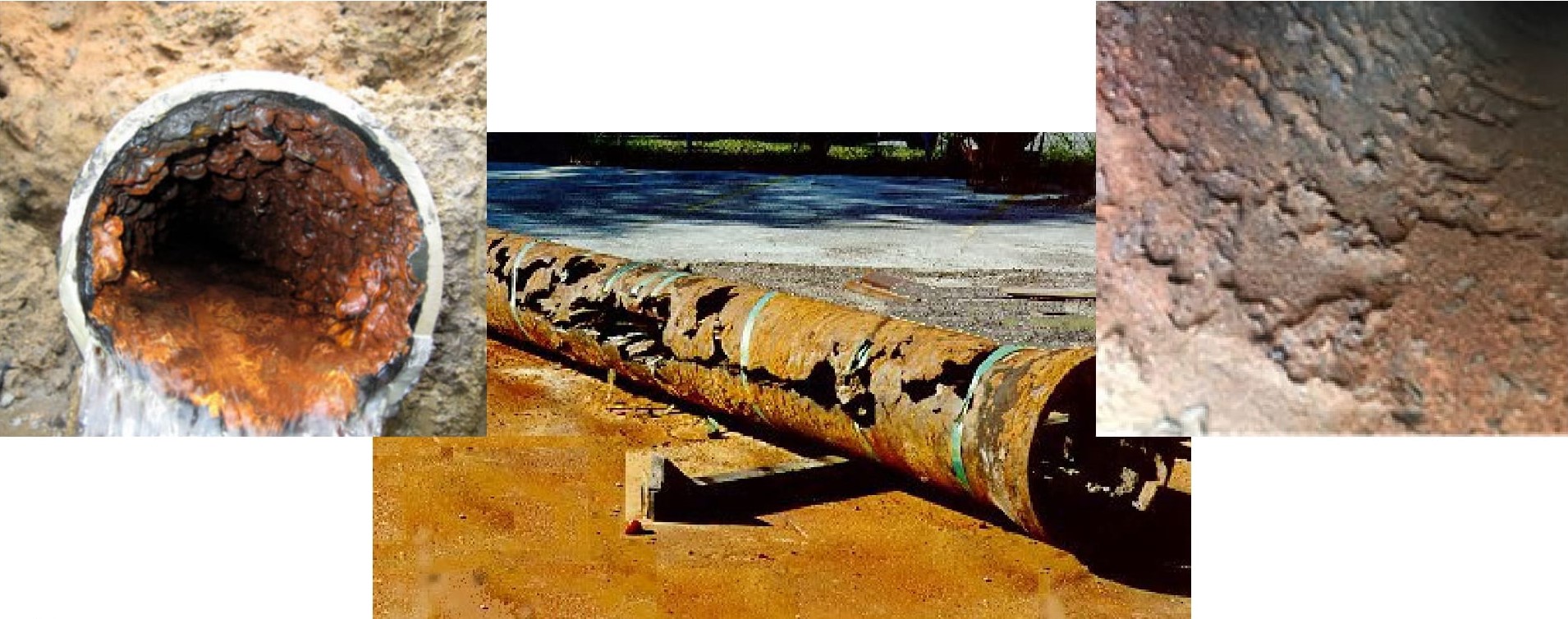

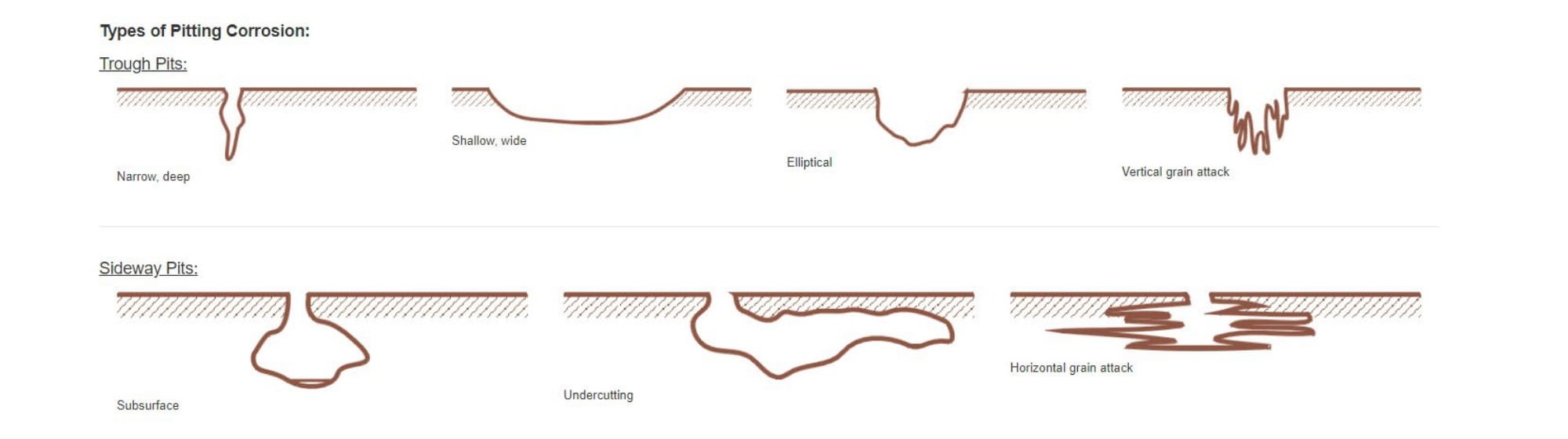

The leading cause of pipeline failure is corrosion. The estimated capital investment needs for water & stormwater pipelines in the U.S. alone is $11.18B USD/ year, a majority of which is replacement cost due to corrosion.¹ The corrosion-related costs of the U.S. oil & gas industry pipelines is $7B USD/ year. ²

Internal corrosion accounts for approximately 60% – 75% of all pipeline incidents caused by corrosion.³

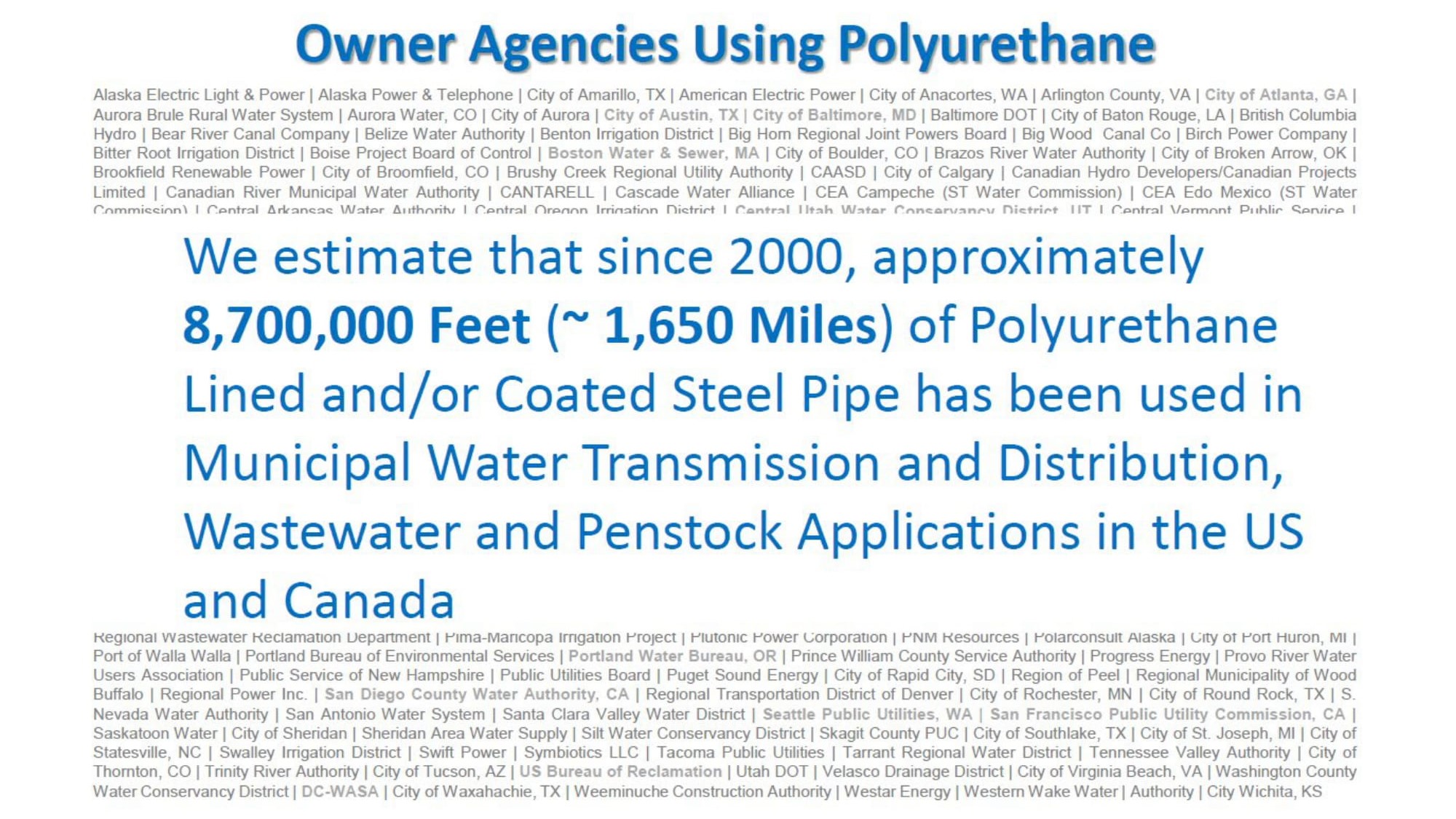

It is inevitable during the handling of thousands of pipes for a project that some will experience impact and flex that push the limits of brittle epoxy linings. Polyurethane linings & coatings flex with the pipe and have no risk of cracking like epoxy. Epoxies will often crack in a tiny spider-web fashion that is difficult to visually detect.

Foreign objects: Experienced pipeline constructors have seen just about everything removed from a pipeline when a cleaning pig is sent through during commissioning. Whether its welding consumables, weld slag, nails, tools, rodents, rocks, etc., it is important that the lining withstand the impact and abrasion from potential foreign objects.

Silt and particles: At high flow rates minute particles and silt can wear linings thin. Polyurethane can be applied at any thickness required for the projected amount of abrasion.

Internal lineup clamps and bending mandrels: If used during construction, heavy internal lineup clamps and bending mandrels have the potential to scratch linings, particularly if they pinch or drag small pebbles through a pipe.