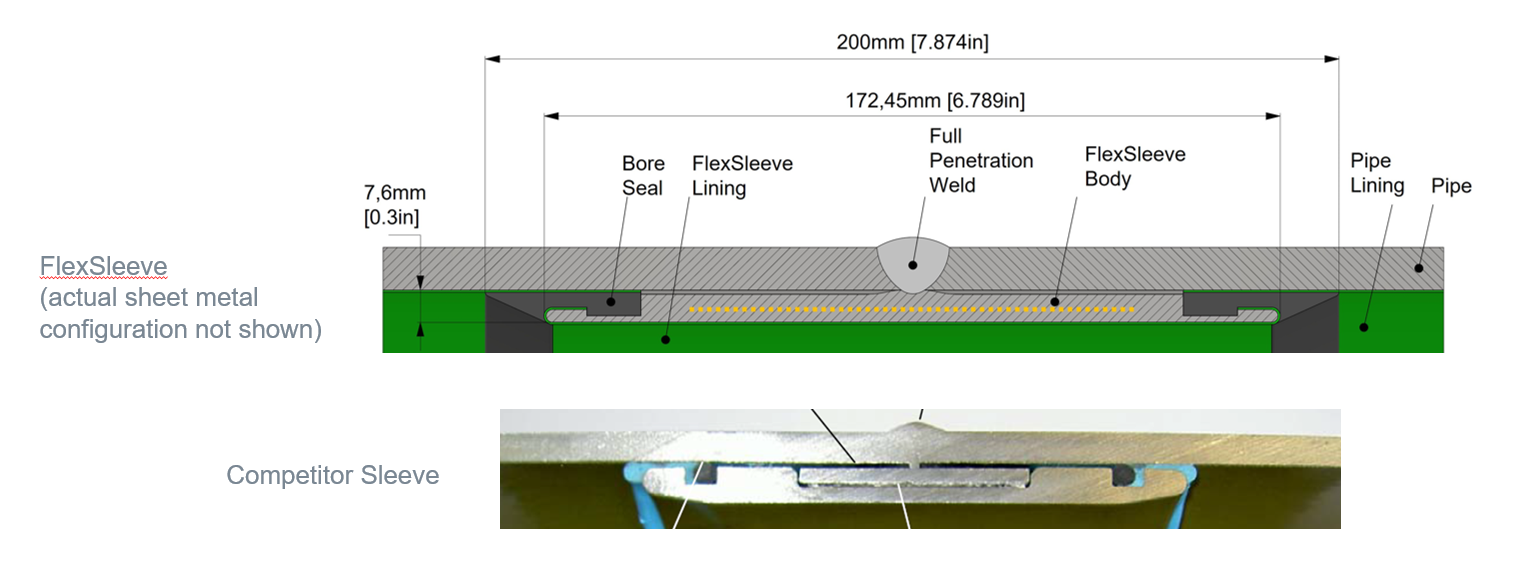

Flexibility: Thin, flexible profile adjusts to pipe ovality for easy insertion and consistent weld & seal quality.

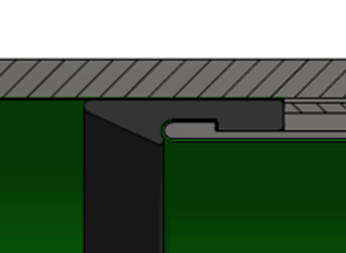

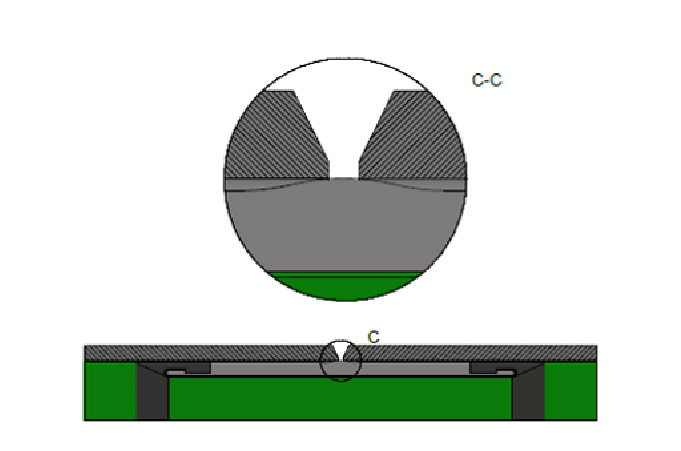

Sealing: Unique bore seal design accommodates pipe ID tolerance and utilizes sleeve flexibility to seal off weld zone.

Heat Resistance: Wide, thick insulation keeps weld heat from damaging protective coating. Permits a long internal pipe coating holdback and normal welding time.

Light Weight: Allows for easy handling and insertion.

Large Diameter Pipelines: Flexibility, seal design, and light weight makes FlexSleeve suitable for pipe up to 80” diameter.

Long Distance Pipelines: Fast and easy sleeve installation. Normal weld times. Functions with internal pipe alignment clamps for automatic welding.

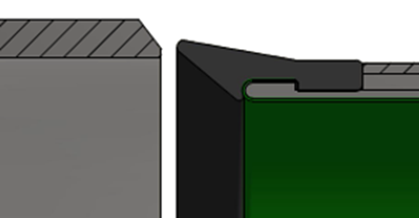

Cross Section Comparison

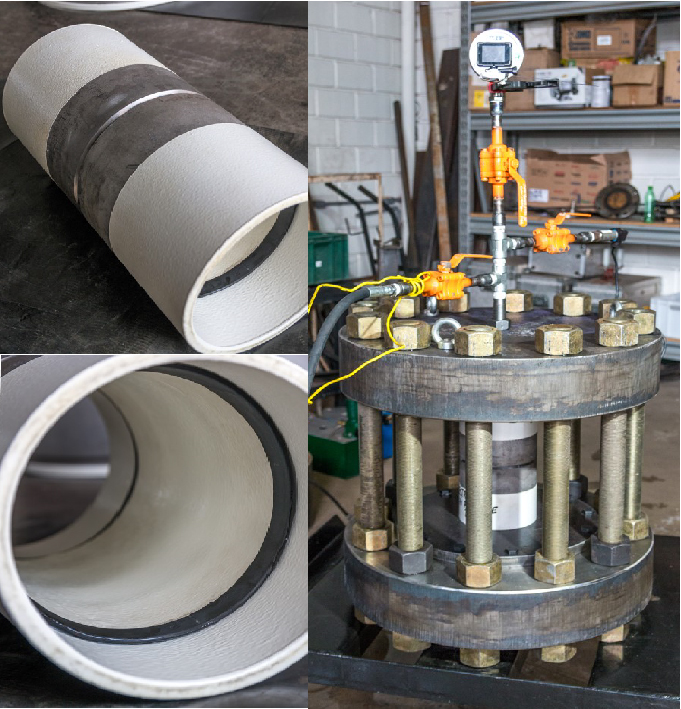

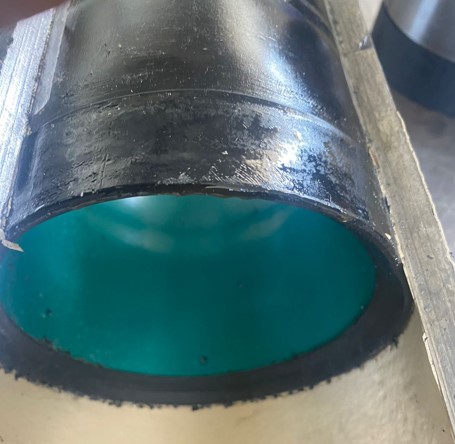

Image of FlexSleeve after hydrotest. Pipe milled away to see bore seal functionality.