What’s Your Solution to Internal Corrosion?

Thermoplastic Liners

Pipe with thick, flexible thermoplastic liners (i.e. HDPE, PVDF, PPS, PEX, PEEK) provides one of the safest ways to transport corrosive commodities.

Thermoplastic lined pipe is used for offshore and onshore oil production, mining slurries, and other aggressive applications.

Welded joint connections are often desired or required, particularly for offshore pipelines.

How It Works

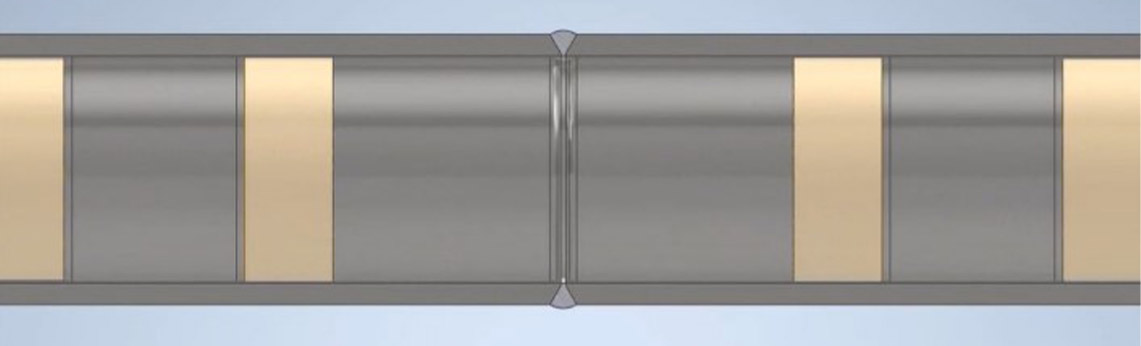

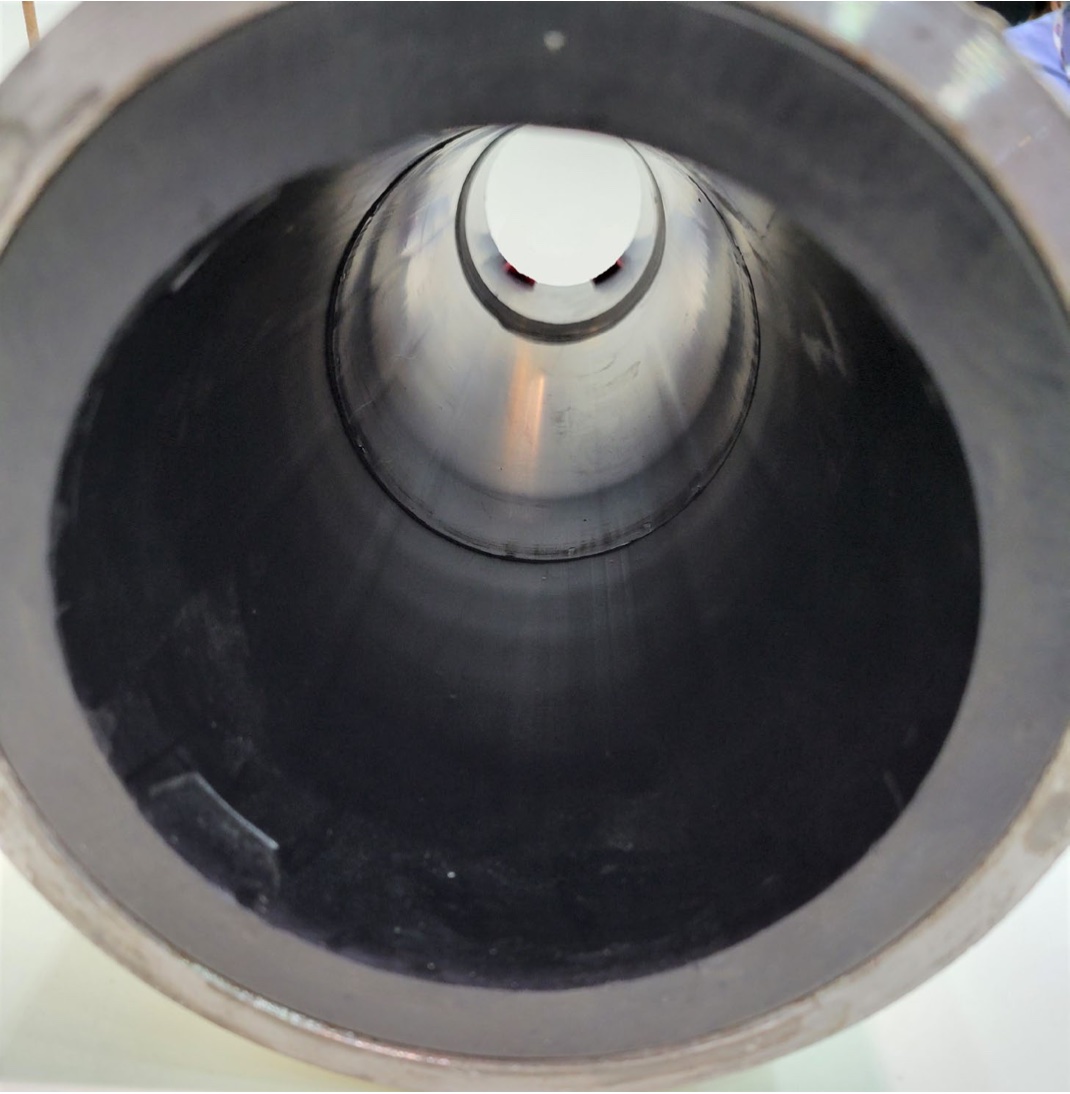

Thermoplastic polymer sleeve bridges the weld zone.

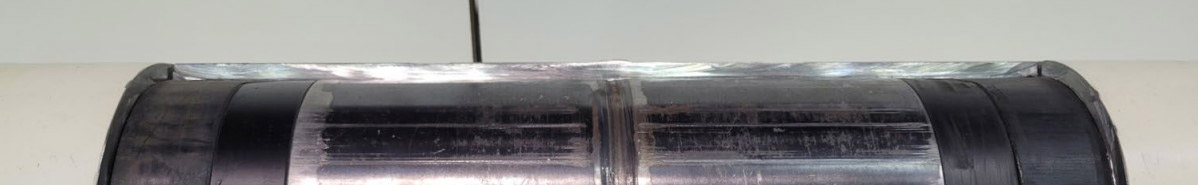

Permits standard full-penetration weld of carbon steel pipe.

Faster joint assembly than any other welded joint solution.

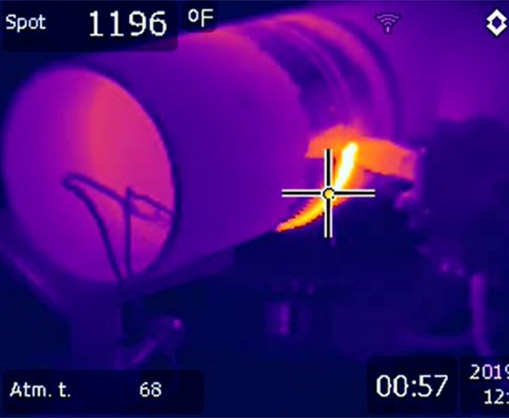

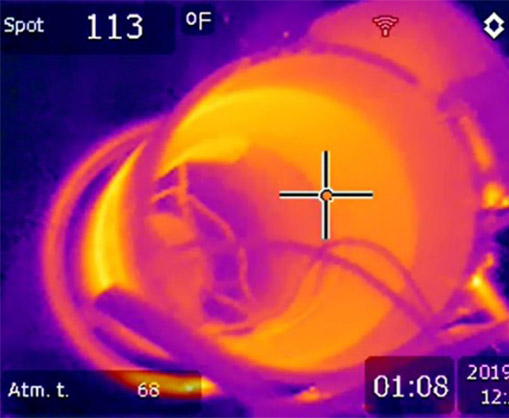

Prevents welding heat from damaging the plastic liner.

Prevents liquids from reaching the bare steel behind the liner.

How It Works

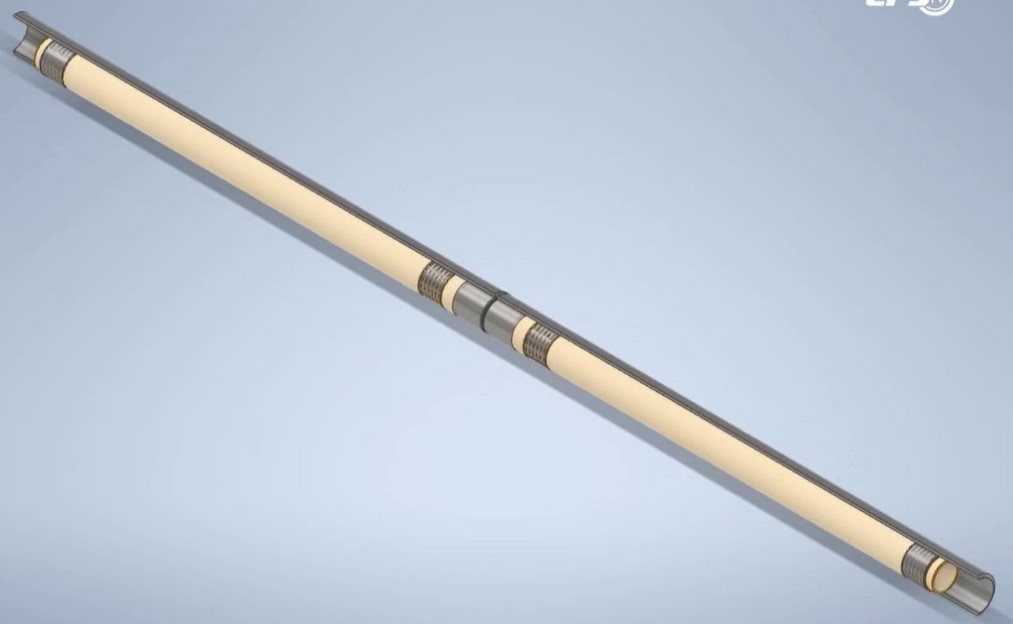

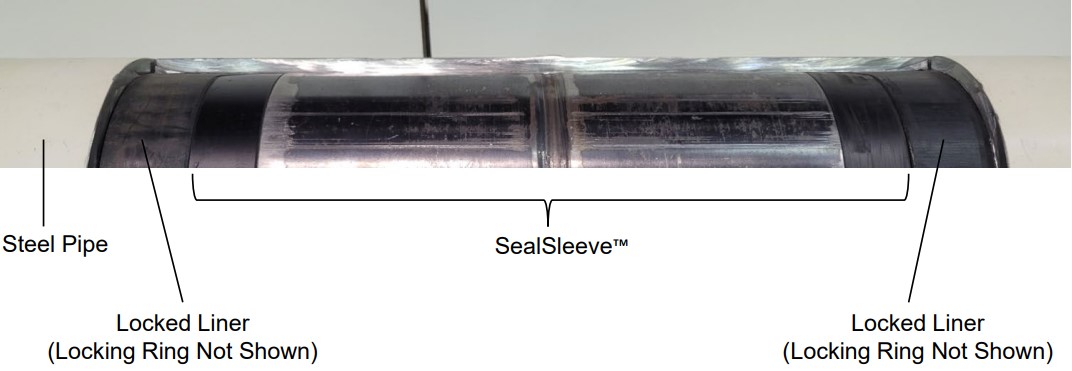

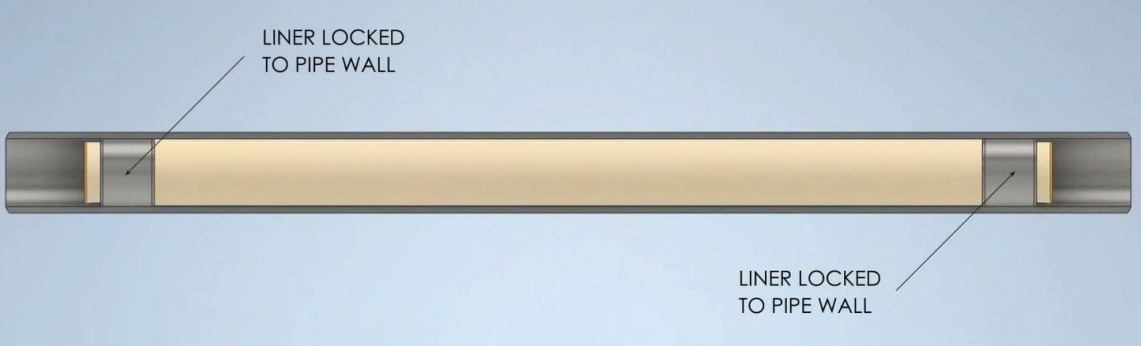

Liner pulled through pipe and locked to pipe wall

Locking rings withstand >30 tons of force, ensuring liner will not move.

Liner insertion and locking to pipe wall may be done in shop, spool base, or in field.

Liner may be installed in any length of pipe section (12m or as long as currently possible).

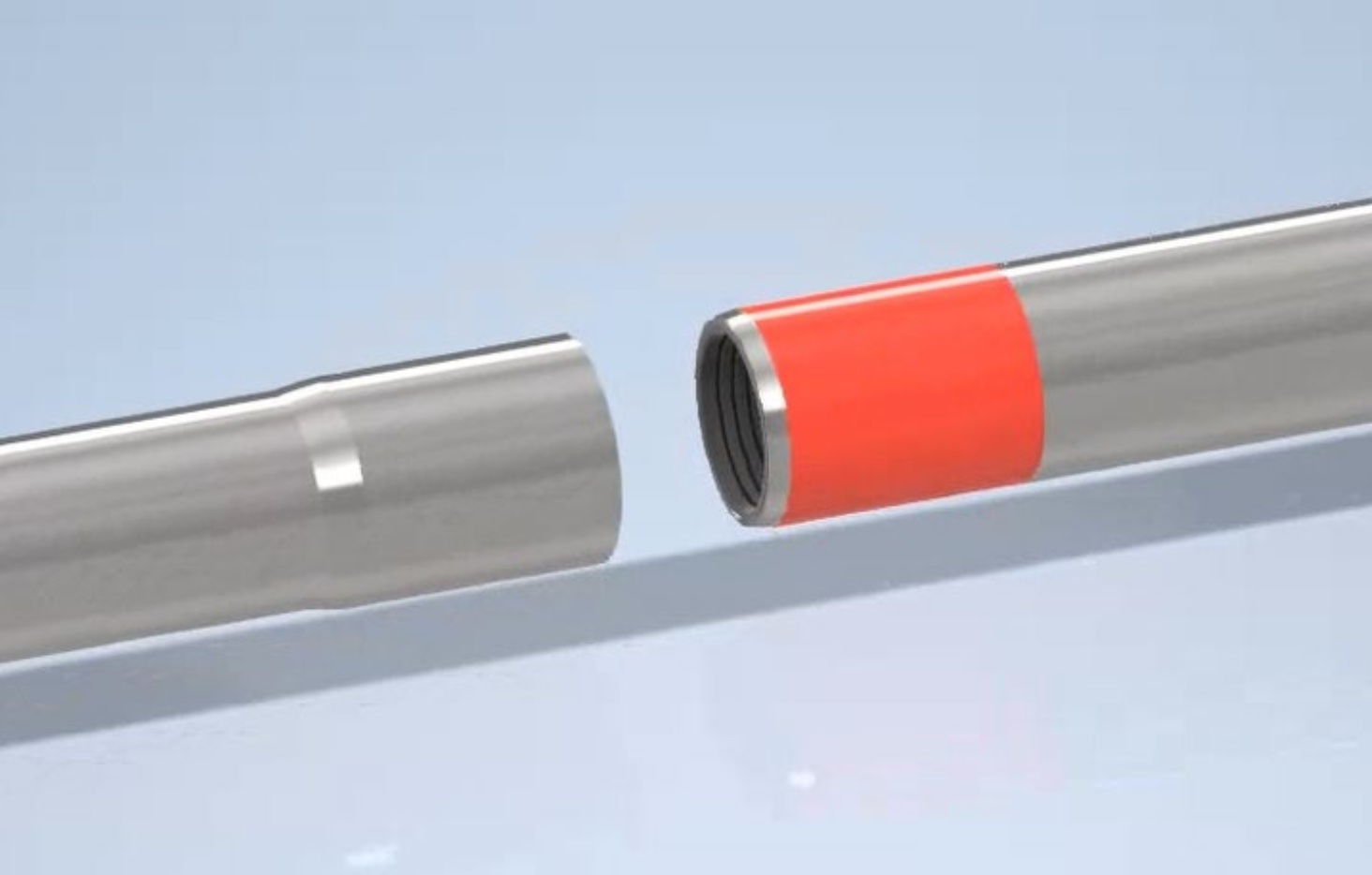

How It Works

SealSleeve™ inserted into pipe ends during pipeline construction & girth weld performed

Hydrostatic Pressure Tests

Hydrostatic pressure tests up to 500 bar (7,200 psi), without a weld.

The higher the pressure, the tighter the seal.

Field Bends, Field Cuts, Fittings

Field Bends, Field Cuts, Fittings

- Plastic-lined steel pipe can be cold bent in the field to any radius the steel pipe can withstand.

- Shop-lined elbows & tees are provided with tangent ends prepared to receive SealSleeveTM

- An adapter is attached to the liner at all field-cuts to allow the use of SealSleeveTM welded joints at tie-in locations.

Shop-Lined vs. Field-Lined Steel Pipe

Technical

Liner is tighter against pipe wall, leaving no annular space between liner & pipe wall.

Liner is sturdier and more collapse-proof than long-distance pull-through liners.

Eliminates mechanical flanges.

Eliminates field thermo-fusion.

Logistical

Construction with shop-lined steel pipe is simpler & more flexible.

Eliminates complexities of field-lining contractor mobilization and coordination with pipeline construction crews.

Shop-lined pipe can be stocked and readily available for quick projects.

Cost

Cost-competitive with field-lining total installed price.

Faster construction schedule = less construction cost.

LinerLockTM for Mechanical Interference Fit Joints

LPS also has the LinerLockTM system for use with mechanical interference fit (MIF) joints*. LinerLockTM uses the same liner-locking and sealing mechanism as SealSleeve with thermoplastic liners offer the following advantages vs. welded joints:

Significantly faster construction with less personnel.

Eliminates NDE requirements.

Eliminates external coating patch requirements.

Less material cost due to elimination of SealSleeve