What’s Your Solution to Internal Corrosion?

Welded Joints for Pipe with Thermoplastic Liners

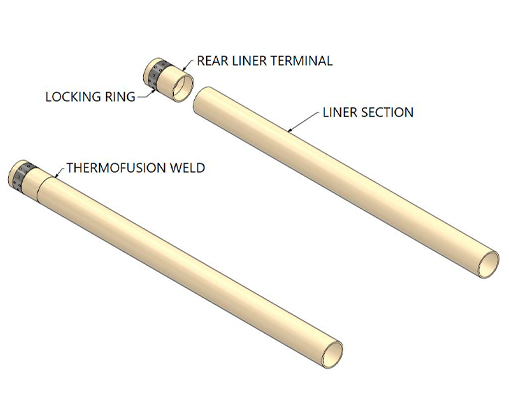

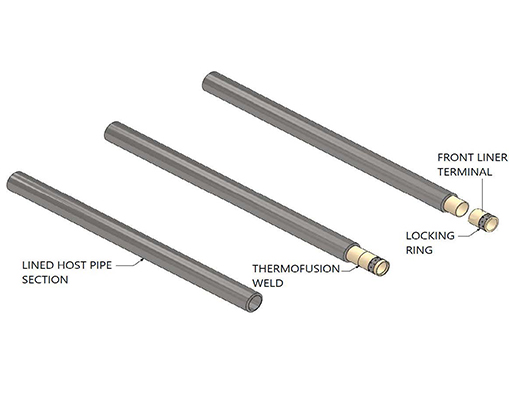

Carbon steel pipe with thermoplastic liners provides the optimal solution for safely transporting hazardous liquids and aggressive slurries. The strength and ductility of steel combined with thick, flexible thermoplastic liners ensures high-pressure pipelines last a very long time.

However, a welded joint solution that protects the weld zone with the plastic liner and permits fast joint assembly has eluded the industry… until now.

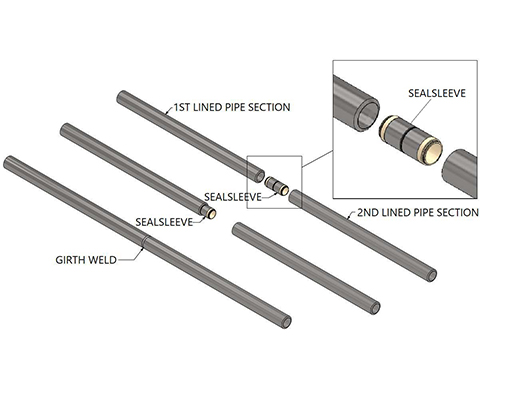

Lined Pipe Systems’ SealSleeve™ utilizes a repeatable and proven sealing technology to bridge the weld zone with a thermally insulated plastic liner. Offshore installation time is a matter of seconds per joint, and onshore installations no longer have to use expensive and leak-prone mechanical joints.

SealSleeve™ allows for the cost-effective use of thermoplastic liners to transport hazardous commodities.

Why SealSleeve™?

Fast J-Lay and S-Lay Offshore Construction : Far faster than joints requiring CRA or plastic electrofusion. SealSleeve™ is never the bottleneck offshore.

Highly Repeatable Joint Quality : O-ring sealing design is well proven and easy to install with consistent quality

High Pressure Applications : SealSleeve™ withstands whichever pressure the pipe can withstand.

Standard Carbon Steel Welds : Permits standard full penetration welds & NDE for carbon steel pipe.

Fast Field Cuts : Unique liner locking system can be quickly adjusted in the field to permit length adjustments for field repairs.

How It Works*

Patents Pending