In the oil and gas industry, numerous technologies and equipment play a crucial role in the extraction and production of petroleum. One such essential component is the sucker rod. Often overlooked, this rod is a critical tool that aids in efficiently pumping oil from underground reservoirs to the surface.

In this post, we will delve into the details of these rods, exploring their purpose, construction, and significance in the oil and gas sector.

What Is Sucker Rod?

Understanding the importance of rods is essential to understand their purpose and functionality. These are long, slender rods made of high-strength steel, typically 25 to 30 feet long, which connect the pumping unit on the surface to the downhole pump in the wellbore.

They form an integral part of the artificial lift system to extract oil and gas from wells. These are designed to transmit the vertical reciprocating motion from the surface to the downhole pump, which aids in the lifting and pumping of fluids.

Functions Of Sucker Rod

This rod plays a vital role in the artificial lift process, which brings oil or gas to the surface when the natural reservoir pressure is insufficient. Here are the primary functions:

Transmitting Power

These rods transmit the reciprocating motion generated by the surface pumping unit down to the downhole pump. This reciprocating motion creates the necessary suction and lifting action to bring fluids to the surface.

Supporting the Downhole Pump

Rods bear the weight of the downhole pump, ensuring it remains suspended at the desired depth within the wellbore integrity. They provide stability and control the vertical movement of the downhole pump assembly.

Withstanding High Loads

These types of rods are designed to withstand high tensile loads and torque during pumping. They must possess excellent strength, durability, and resistance to corrosion to ensure efficient and reliable oil and gas production.

Types of Sucker Rod

Various types of these rods are available, each designed to meet specific operational requirements and conditions in the oil and gas industry. Here are some common types:

Standard Rods

Standard rods are the most commonly used type. They are made of high-strength carbon or alloy steel and come in different sizes and lengths. Standard rods are typically solid, meaning they have a continuous body without hollow sections.

These rods are suitable for most well conditions and provide reliable performance in typical oil and gas production operations.

Hollow Rods

Hollow rods have a hollow interior, offering advantages in specific well situations. They are lighter than standard rods, which can reduce the load on the pumping unit and improve pumping efficiency.

Hollow rods are often used in wells with high fluid volumes, viscous fluids or when there is a need to reduce the weight of the rod string.

Continuous Rods

Continuous rods are specially designed for wells with deviated or crooked boreholes. These rods have flexible joints or couplings that allow them to bend and accommodate the wellbore’s shape without the risk of breakage.

Continuous rods help minimize the stress and fatigue in deviated wells, ensuring reliable and continuous operation.

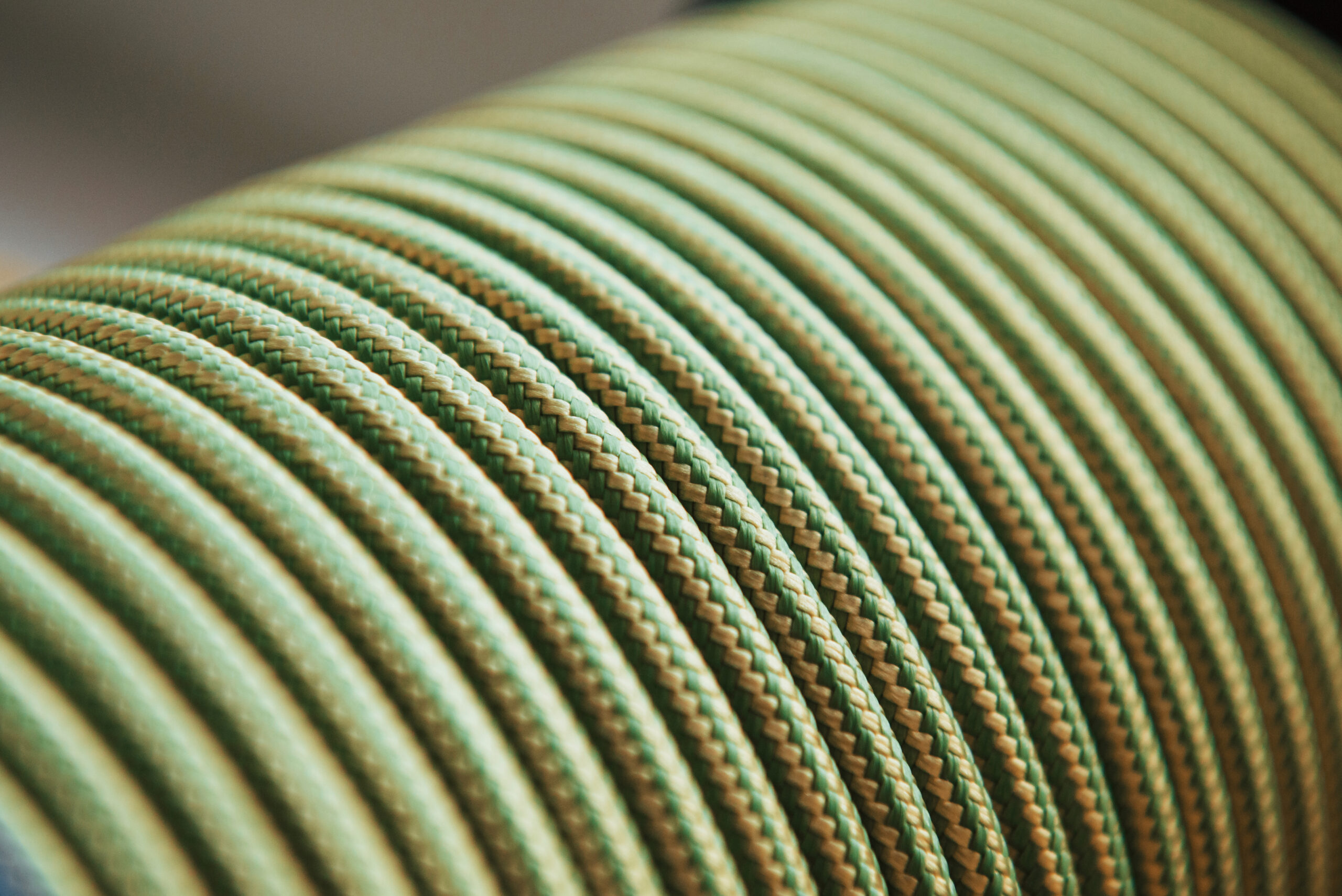

Spray Metal or Fiberglass Rods

Fiberglass or spray metal rods are used in corrosive or high-temperature environments where traditional steel rods may not be suitable. Spray metal rods are coated with a layer of corrosion-resistant material, such as aluminum, to protect against chemical reactions.

Fiberglass rods are composite materials that offer excellent corrosion resistance and strength. These alternative materials provide durability and performance in harsh well conditions.

Polished Rods

Polished rods are not technically rods but are an integral part of the rod string. They connect the downhole pump to the rod string and transmit the reciprocating motion from the surface unit.

Polished rods are usually steel and have a smooth, polished surface to minimize wear and friction between the rod string and the pumping unit.

Importance of Sucker Rod

Production Efficiency

Rod pumping systems are widely used for artificial lift operations worldwide, making them a vital tool for increasing production efficiency. They allow for the economic recovery of oil and gas resources, even from low-pressure reservoirs.

Versatility

These rods are compatible with various downhole pumps, making them versatile for different well conditions and reservoir characteristics. They can be tailored to specific well depths, fluid viscosities, and production rates.

Cost-Effectiveness

These rod systems are relatively simple and cost-effective compared to other artificial lift methods. They require less initial investment and maintenance, making them suitable for onshore and offshore applications.

Durability and Reliability

Rods are engineered to withstand harsh downhole conditions, including high loads, corrosive environments, and extreme temperatures. Their strength and durability ensure long-lasting and reliable operation.

Artificial Lift

These rods are an integral part of the artificial lift system, which helps overcome the natural decline in well pressure over time. By transmitting the reciprocating motion from the surface to the downhole pump, rods create the necessary pressure differentials to lift fluids, including oil, to the surface.

Monitoring Capabilities

These rods provide a means for monitoring downhole conditions. By analyzing the rod’s behavior, including vibrations, load, and stress, operators can gain valuable insights into well performance, downhole conditions, and potential issues like rod fatigue or pump failures.

Load Bearing and Stability

Rods are subjected to significant operational stresses, such as tension, compression, and bending forces. They must withstand these loads while maintaining structural integrity. High-quality rods possess excellent strength, durability, and resistance to corrosion, ensuring their reliability and longevity under challenging downhole conditions.

Transferring Power

Rods are a conduit for transferring mechanical power from the surface pumping unit to the downhole pump. This power is used to lift the fluids, such as oil and gas, to the surface. As the surface unit reciprocates, it gives up-and-down motion to the rods, which drives the downhole pump.

Conclusion

In the complex world of oil production, the sucker rod often goes unnoticed, but its significance cannot be overstated. Rods form the backbone of artificial lift systems, enabling oil extraction from wells efficiently and reliably.

Their construction, versatility, longevity, and cost-effectiveness make them vital in the oil and gas industry. By understanding the role and importance of rods, we gain a deeper appreciation for the technologies that make oil production possible, ensuring the world’s energy needs are met.

If you need any kind of high-quality and trustworthy pipeline services, visit Lined Pipe System now!

FAQs

What is a sucker rod, and what is its purpose?

A sucker rod is a long, slender metal rod, typically high-strength steel. Its purpose is to be a mechanical link between the surface pumping equipment and the downhole pump in an oil or gas well. It transfers power from the surface unit to the downhole pump, allowing oil and gas extraction from the well.

Why are sucker rods important in the oil and gas industry?

Sucker rods play a crucial role in efficiently and safely operating oil and gas wells. They help transfer power to the downhole pump, ensuring the continuous pumping of fluids to the surface. Sucker rods also provide load-bearing capabilities and stability, allowing for the smooth operation of the pumping system.

What are the different types of sucker rods?

Several types of sucker rods are available, including standard rods, hollow rods, continuous rods, spray metal or fiberglass rods, and polished rods. Each type is designed to meet specific operational requirements and well conditions. Hollow rods, for example, are lighter and suitable for high fluid volumes, while continuous rods are flexible and ideal for deviated wells.

How do sucker rods contribute to pumping efficiency?

Sucker rods ensure efficient pumping by transferring power from the surface unit to the downhole pump. The reciprocating motion the surface unit generates is transmitted through the sucker rods, creating the up-and-down movement required for fluid extraction. This efficient transfer of power helps optimize production rates and maintain the well’s productivity.

Are sucker rods susceptible to wear and corrosion?

Sucker rods are subjected to significant stresses and harsh downhole conditions, which can lead to wear and corrosion. However, high-quality sucker rods are made from durable, corrosion-resistant materials like high-strength steel or alternative materials like fiberglass. Proper maintenance and regular inspection can help identify and address any wear or corrosion issues to ensure the longevity and reliability of the rods.

How do sucker rods contribute to well safety?

Sucker rods are crucial to well safety by maintaining stability and structural integrity. They are designed to withstand tension, compression, and bending forces, ensuring the safe operation of the pumping system. Well-designed and properly maintained sucker rods contribute to the overall safety of the well and help prevent accidents or failures that could result in production downtime or environmental damage.

Can different well conditions affect the selection of sucker rods?

Yes, different well conditions can impact the choice of sucker rods. Factors such as fluid volume, viscosity, temperature, and corrosive properties of the well fluids must be considered. For example, wells with corrosive fluids may require spray metal or fiberglass rods, while deviated wells may benefit from continuous rods.