See some most important field joint coating considerations.

An immediate objective of applying external coatings on pipelines is corrosion control. However, coating systems for corrosion control are designed to provide mechanical security during installation. A Field joint is an area where two pipeline sections meet and are welded together, such as a girth weld. This area must be implicated with anti-corrosion layers to protect the essential steel joint from corrosion.

During the pipeline installation, the field joint coating process is frequently a time-consuming stage. Usually, 15 to 20 minutes are required to apply a field common coating consideration properly.

Types Of Field Joint Coating

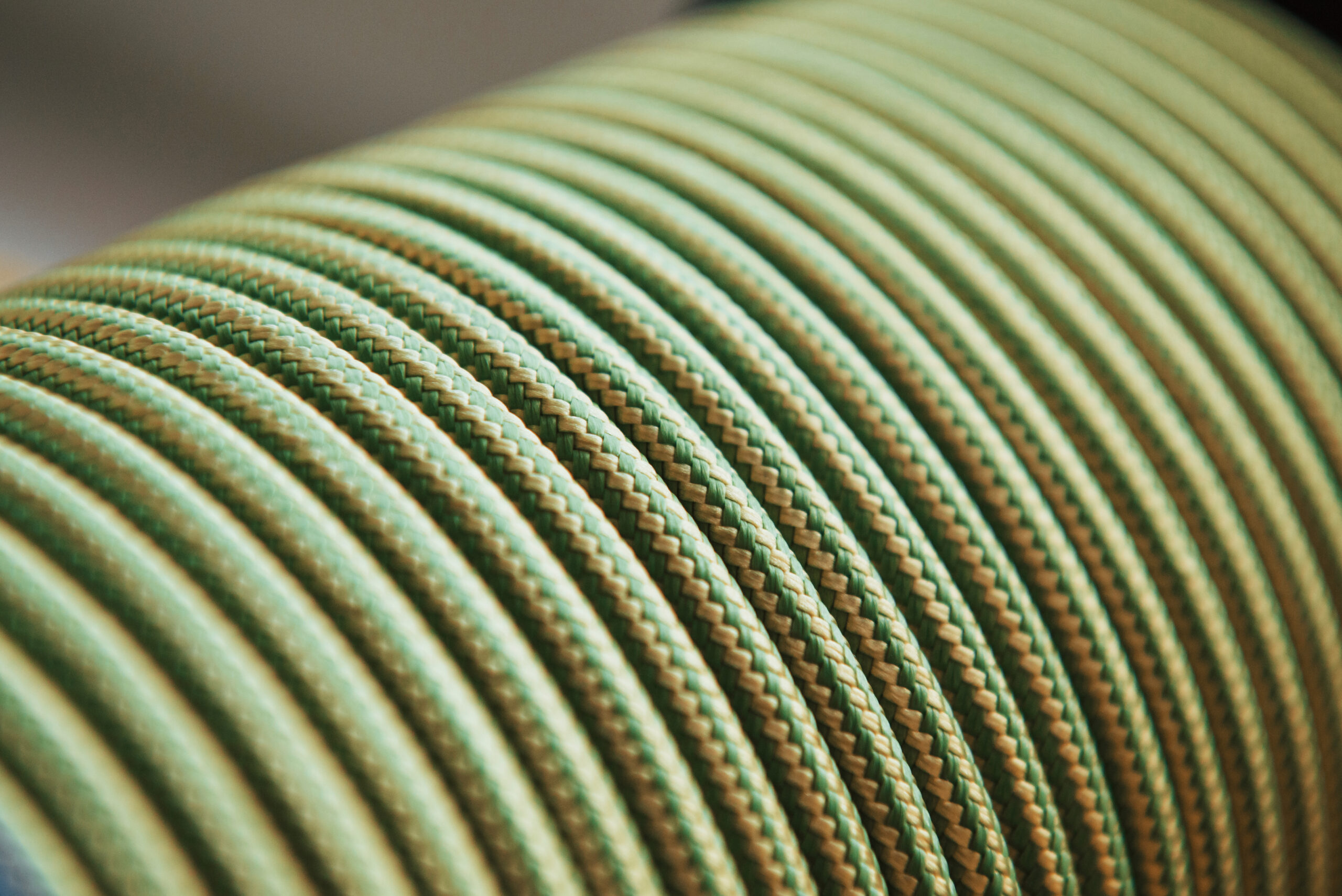

There are many types of joint field coating. A few are named below;

- Polyurethanes

- Fusion-bonded Epoxies(FBE)

- Wax tapes

- Heat shrinkable sleeves

- Petrolatum tapes

- Polypropylene(PP)

- Polyethylene(PE)

Steps Joint Coating On Pipelines

Step 1 – Surface Preparation

Step 2 – Induction heating

Step 3 – Joint Coating

Field Joint Coating Considerations

Field joint coating is the best strategy, and some of its considerations are given below;

Bond and Strength (a critical factor in the joint coating)

Steel pipes are typically coated with a corrosion precluding system at the factory and on the construction site. When the particular steel pipes are welded together to evolve pipelines, the corrosion prevention layer applied in the factory is damaged.

When the pipes have been welded together, a new coating is applied to the welded area to protect it from corrosion and mechanical loads. This process gives enough Strength to the joint to fight against corruption and other environmental factors.

Preheating Elements

It is essential to comprehend the heating surface preparation series. For example, if an open torch is used, it is reasonable to preheat the surface before abrasive discharge to eradicate the risk of flash rusting on the surface. The induction coil is the best method, but unfortunately, they are not always available.

Quality Control

The quality control strategy should be acclimated according to environmental conditions and fixing mechanisms. Many of the testing protocols are developed for ordinary temperatures. QC testing, such as adhesion, Shore D hardness, etc., is not meant to perform at lower temperatures.

It would help if you inspected the inspection testing plan and accepted recourses, such as fellow plates, or other test methods that are better suitable for lower temperatures, should be used.

Sheltering the Joint Coating

The JFC (joint field coating) area should be protected during the installation and preheating. Its joint field coating will ensure that it covers the joint from corrosion, cold wind, and weather. It is necessary for such conditions where the environment could interfere with the coating curing process.

How And Why Do You Carry Out Pipeline’s Coating Rehabilitation?

Pipeline coating rehabilitation is much more necessary. Pipeline coating rehabilitation should be viewed when the current coating compromises the virtue of the pipeline. No identified rule or standard for defining coating conditions might risk the pipeline’s integrity. Main exertions for pipeline coating rehabilitation include:

- Pipeline section Excavation

- Removal of the existing coating

- Cleaning surface (from dust, grease, or corrosion)

- New coating application and then repair

- Backfilling

How Do You Overcome Coatings Failures?

The pipeline coating industry is well-known, and acknowledged that the main reason for coating failures is the consequence of horrible coating conditions. This condition is generally related to surface preparation, weather, and salt contaminants. Another reason for coating failure is due to wrong coating selection.

Conditions like operating temperature, pipe diameter, backfill texture, and mechanical impacts are necessary to select a suitable coating system. The best way to overcome coating failures is to examine all these parameters discussed above closely.

How Is Field-Joint Coating Different From Mainline Coating?

Mainline coating has only to ensure gluing to the pipe surface only. At the same time, the joint field coating has to ensure bonding between the mainline coating and field joint coating. It is easy to maintain quality because the factory applies the mainline coating, and there is no time restriction.

But it is difficult to maintain quality in field joints coating because these are applied on the field. Also, there are time restrictions, so the coating process has to finish quickly. Mainline coatings can be used efficiently in factories, while joint field coatings must apply under severe environmental conditions.

FAQs

What does Field Joint mean?

The field joint is where two pipelines are linked or welled together. This welded area that joins two pipelines together is called a Field joint.

What does a Heat-shrink sleeve mean?

Heat-shrinkable sleeves are the most widely used technology worldwide for corrosion protection because they are easy to install, provide superior protection, and are budget-friendly.

What does pipeline coating mean?

A pipeline coating is a cost-effective and possible solution to keep pipelines’ integrity. This coating provides constant protection that saves the pipelines from the destructive effects of corrosion. Pipeline coating is one of the most faithful corrosion prevention techniques today.

How to control corrosion on pipelines?

The best way to keep the pipeline safe from corrosion, you should have to apply some anti-corrosion coating on the pipeline. This anti-corrosion layer saves the pipeline or joint from severe environmental factors.

What is Girth weld coating?

A girth weld coating is a protective fluid coating applied to the exterior metal surface of two pipes linked along their girth during pipeline construction. These coatings are beneficial that are designed to prevent corrosion and are usually produced in the form of polyurethane or epoxy.

Final Thoughts

Field joint coating is critical and valuable for pipelines to protect both the joints and the outer layer of the pipeline. Field joint coating is considered the most precise technique for corrosion prevention and enhancing pipelines’ life span.

After reading this article, you can understand the field joint coating considerations. We have also discussed the types of Field joint coating. After reading this article, you can understand the importance of joint field coating.