ROI Comparisons: Abrasive Slurry Pipelines

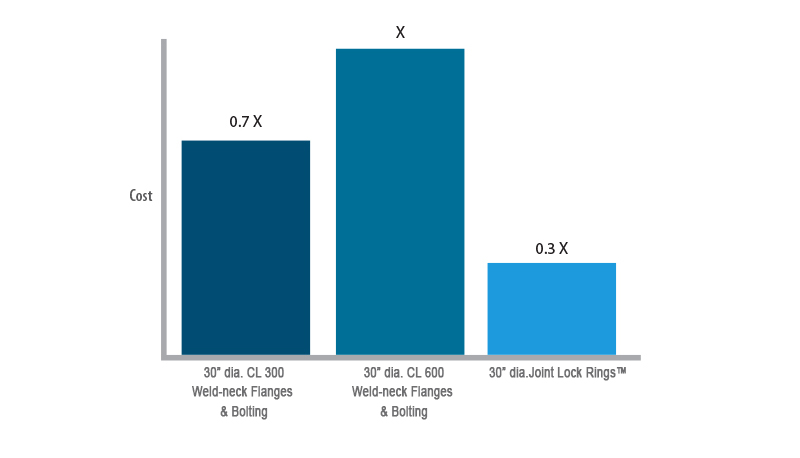

Pipelines with highly abrasive slurries require abrasion resistant polyurethane or rubber linings. The most common method of joining rubber and polyurethane lined pipe sections is bolted flanges. The following is a material cost comparison of high-pressure flanges and bolting vs. Joint Lock Ring™️ with welded joints.

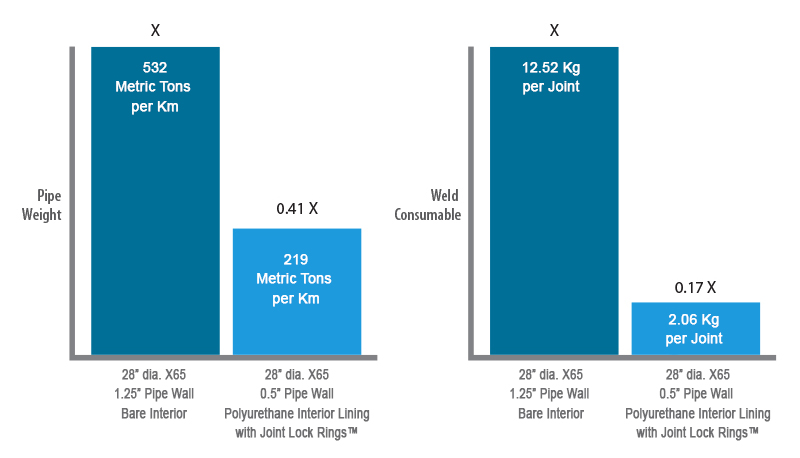

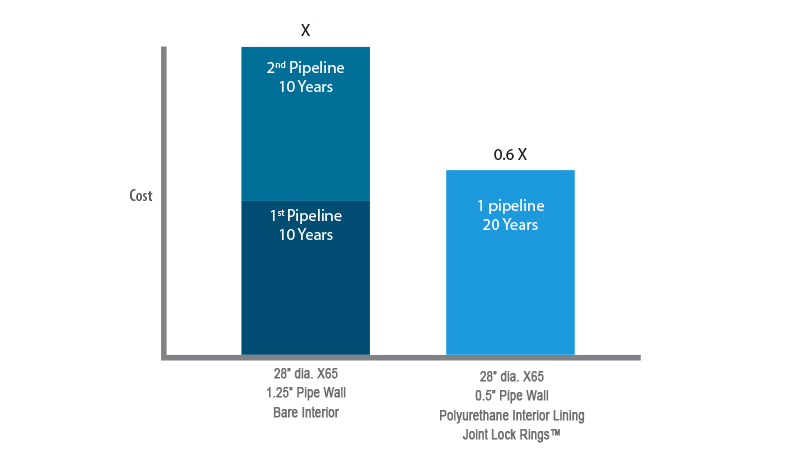

Bare pipelines with welded joints are commonly used for long-distance high-pressure slurry pipelines. The wall thickness is increased to allow for erosion and corrosion. Even with the extra thickness these pipelines must be constructed twice or even three times over the period that one rubber or polyurethane lined pipeline would last.

The following are CapEx comparisons over 25 years and construction considerations for bare vs. lined pipe.

CapEx Cost Comparisons

Bare Pipe vs. Lined Pipe w/ SealSleeve™️ system

Flanges vs. SealSleeve™️