Project Details

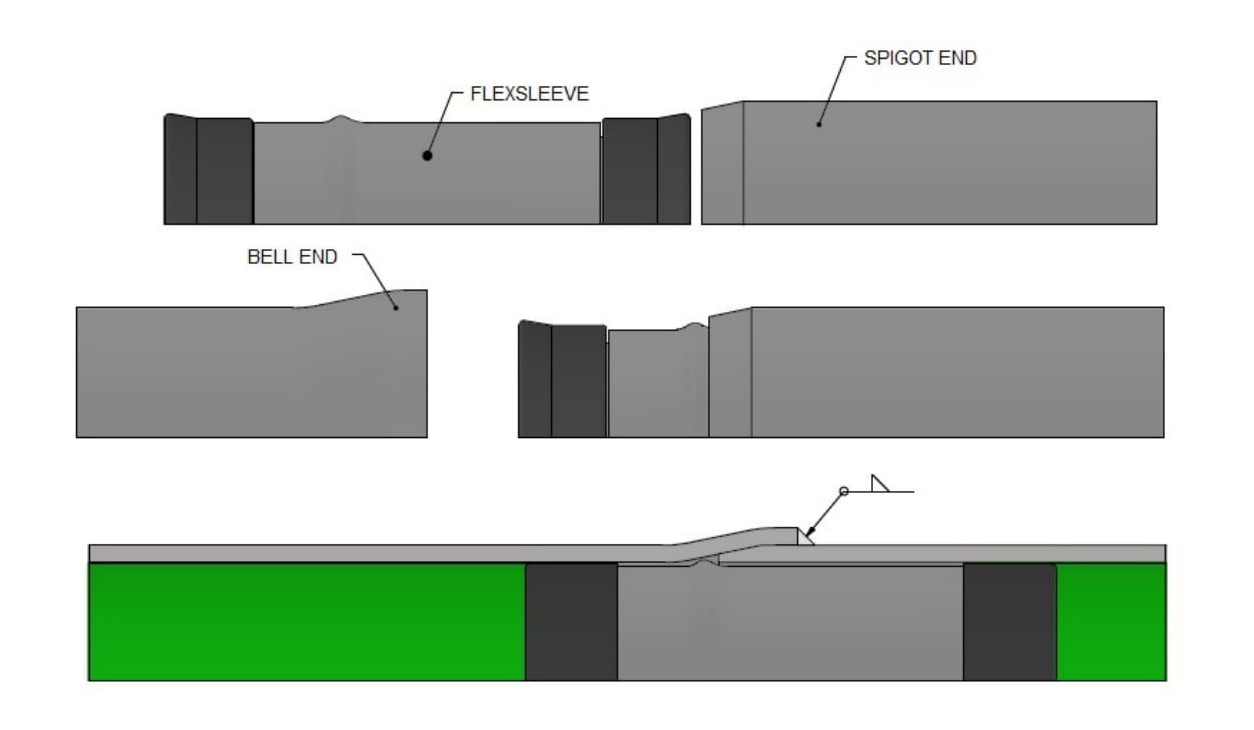

Pipeline Details: 28″ & 24″ dia. x 92km potable water pipeline. Spiral welded pipe with butt-strap joints (See pg. 2 for diagram). Internally coated with liquid epoxy.

Owner / Location: COPASA Water Authority, Minas Gerais, Brazil

Contractor: OEC, subsidiary of Novonor

Install Dates: August 2021 – January 2022

Quantity of FlexSleeves Installed: 432 ea.

Current Status: All FlexSleeve joints passed visual inspection and hydrotests and pipeline was commissioned in April 2022.

Video: Watch Now