Carbon steel pipe with welded joints provides optimal strength and ductility for pipelines. However, carbon steel will corrode without good external and internal protective coatings.

The big question is: what’s the best way to protect the interior steel of the weld zone from corrosion?

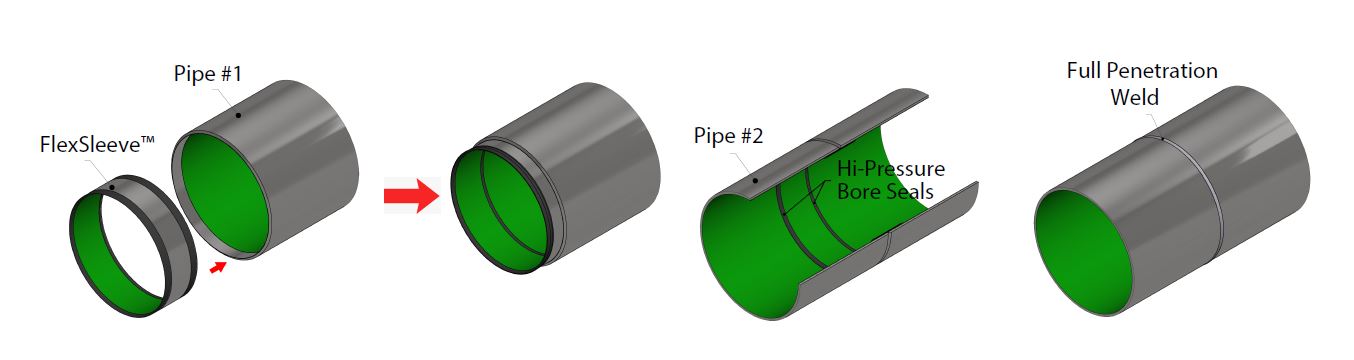

The options are limited and Lined Pipe Systems’ FlexSleeve® is the simplest and most effective. It’s easy to install, permanently keeps liquid from reaching the joint, and permits fast pipeline construction.

The FlexSleeve® represents a quantum leap from the heavy, stiff internal sleeves that have been on the market for decades.